About Us

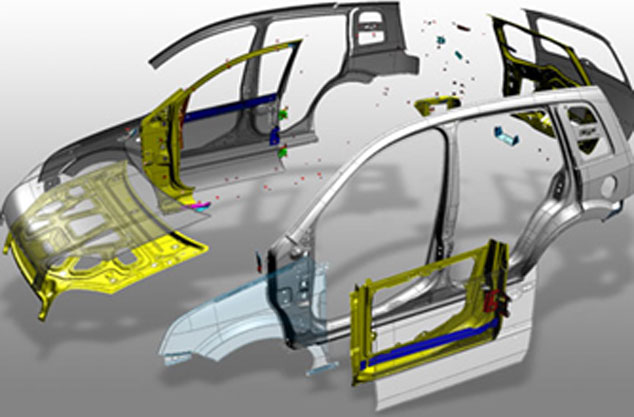

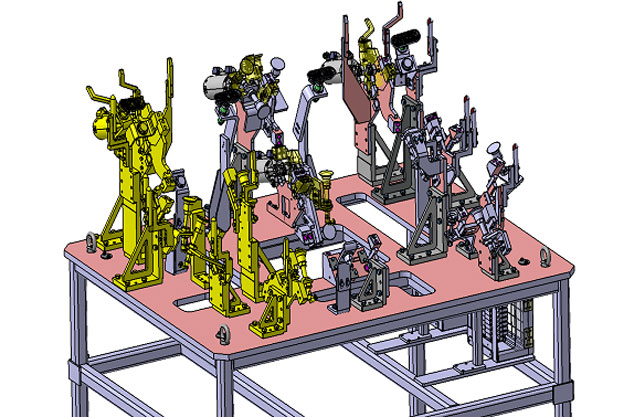

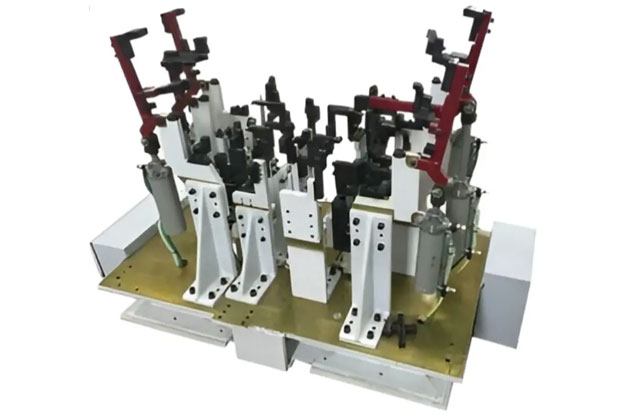

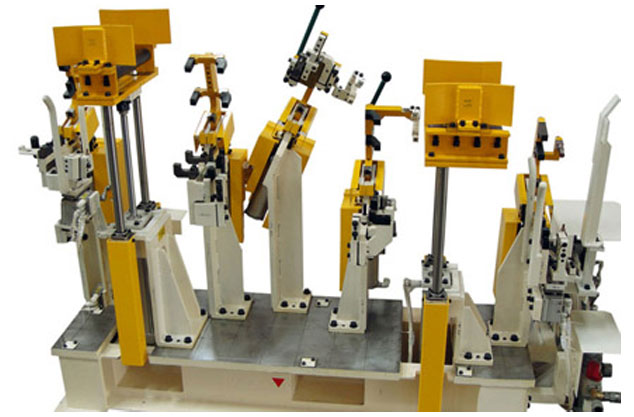

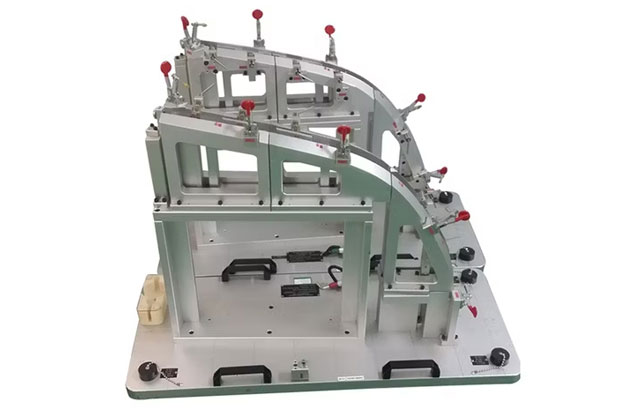

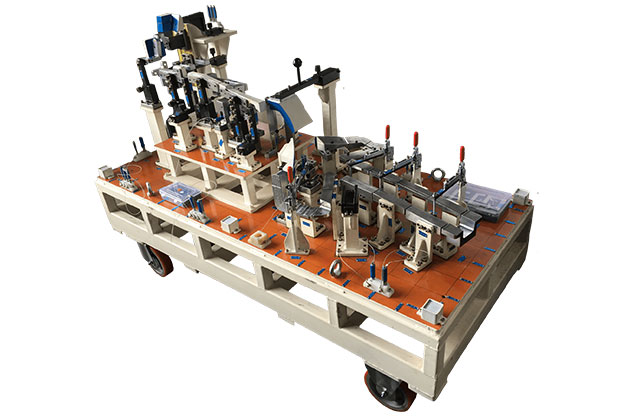

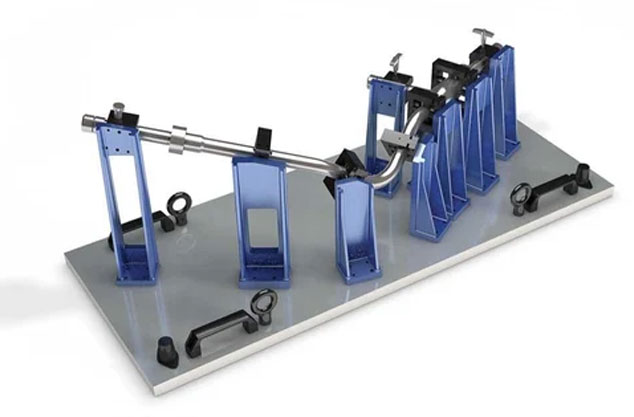

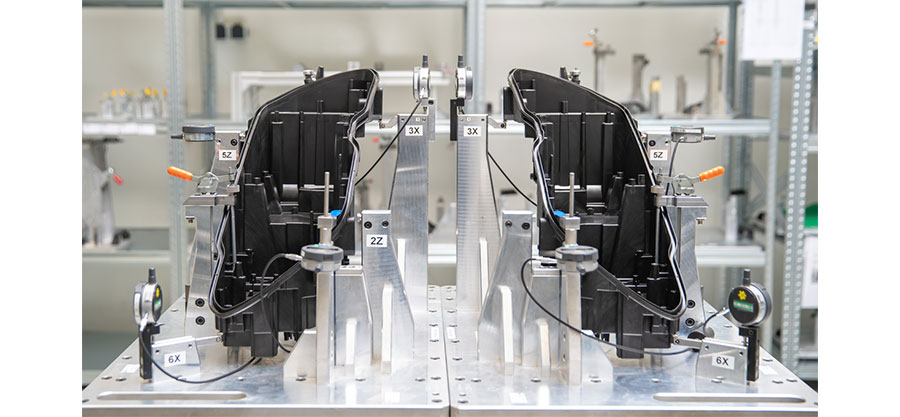

SYDs FutureDrive Solution Pvt Ltd incorporated in the year 2024. Actively involved in BIW fixtures designing, manufacturing and assembly

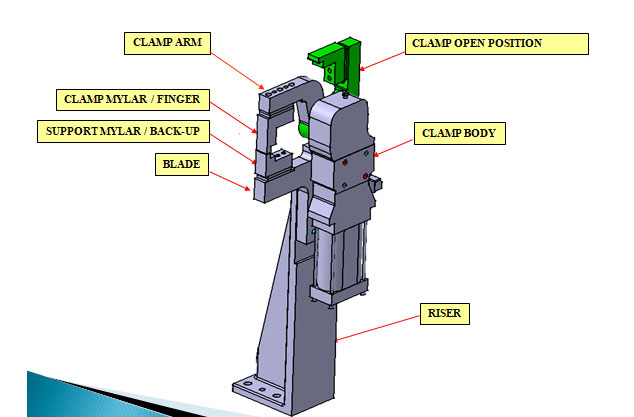

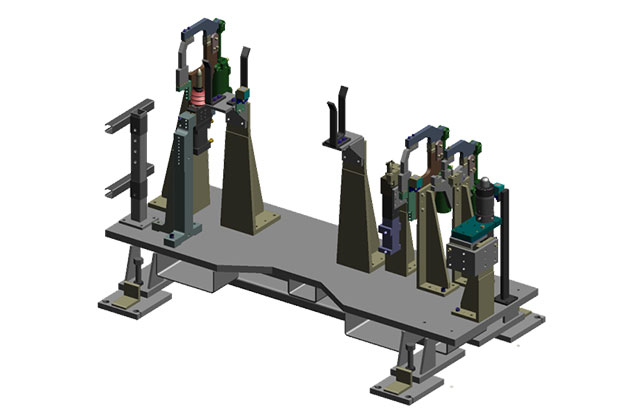

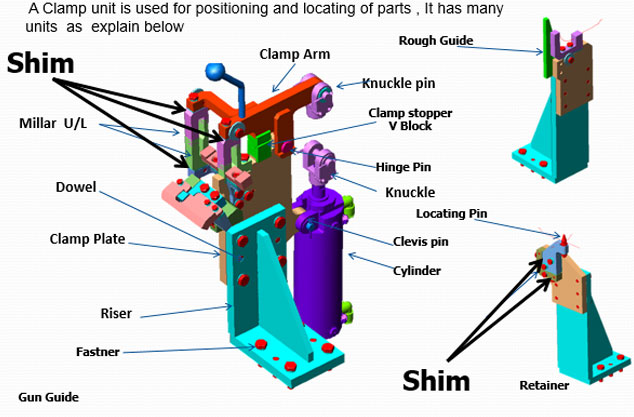

Welding fixtures are essential tools used in the manufacturing process to securely hold components in place during welding operations. These fixtures ensure that parts are precisely aligned, positioned, and stabilized while welding, which is crucial for achieving strong, high-quality welds. By providing consistent and repeatable positioning, welding fixtures help improve the accuracy and efficiency of the welding process, reducing the risk of defects such as misalignment or distortion. Typically constructed from durable materials like steel or aluminum, welding fixtures are custom-designed to suit the specific geometry and size of the parts being welded. They can accommodate complex shapes and allow for easy handling and manipulation of components during the welding process. Welding fixtures are widely used in industries such as automotive, aerospace, and heavy machinery, where structural integrity and precision are paramount. By ensuring the parts are properly held during welding, these fixtures contribute to reducing rework, minimizing scrap, and maintaining consistent product quality throughout the production cycle.